Researchers are finding innovative ways to recycle textile waste and reduce its environmental footprint.

Most of us don’t think twice about what happens to old clothes, linens, and fabrics once we toss them out—but the problem is bigger than it seems. Around the world, mountains of textile waste are piling up, straining landfills and fueling pollution. Now, a wave of new technology is changing that story. Scientists and innovators are finding smart ways to turn discarded textiles into something useful, giving waste a surprising—and much-needed—second act.

1. The World’s Growing Pile of Textile Waste

Every year, the world produces more than 90 million tons of textile waste, much of it from clothing, upholstery, and industrial fabrics. Only a fraction is reused or recycled, while the majority ends up buried in landfills or incinerated.

According to the Ellen MacArthur Foundation, the equivalent of one garbage truck of textiles is landfilled or burned every second. This growing waste stream contributes to greenhouse gas emissions, chemical pollution, and microplastic release into waterways.

2. Why Recycling Textiles Is So Difficult

Unlike glass or aluminum, textiles are often made from complex blends of natural and synthetic fibers, making them hard to separate and recycle. Many fabrics also contain dyes, coatings, or elastic materials that interfere with traditional recycling methods.

These technical challenges mean that less than 1% of used textiles are currently recycled into new textile fibers. Overcoming these barriers requires advanced technologies capable of breaking materials down to their basic components.

3. Mechanical Recycling Gives Old Fabrics a Second Life

Mechanical recycling remains one of the most common methods for repurposing textile waste. In this process, fabrics are shredded into fibers that can be spun into yarn or used for other materials.

While this approach can’t restore fibers to their original strength or quality, it’s useful for creating products such as padding, insulation, and nonwoven fabrics. Advances in fiber-sorting systems are helping mechanical recycling recover more material with less contamination.

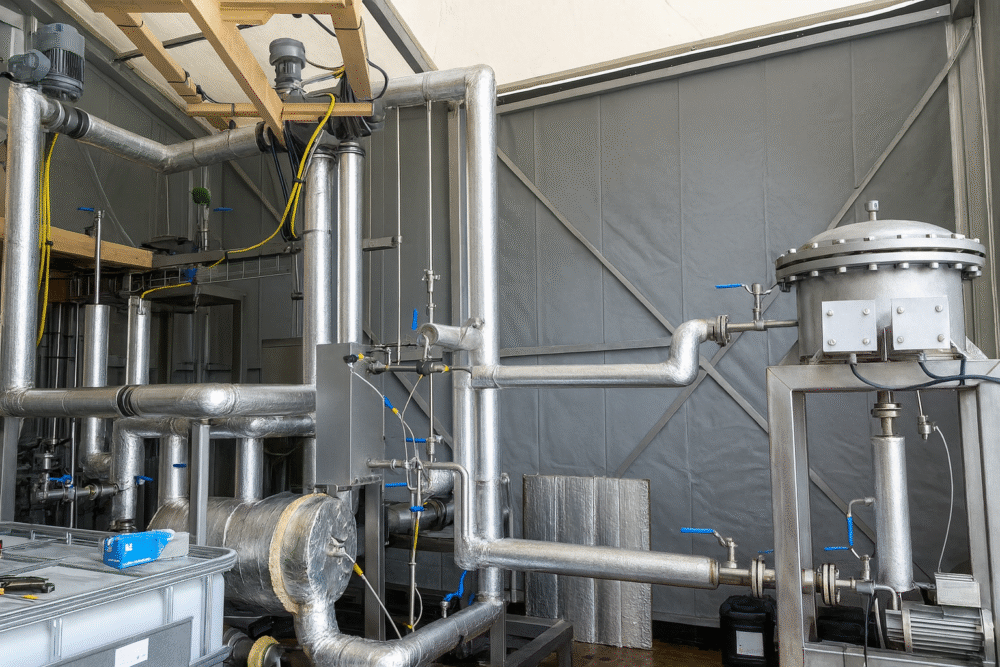

4. Chemical Recycling Is Unlocking New Possibilities

Chemical recycling goes a step further by breaking down textiles into their molecular building blocks. Using solvents or enzymes, scientists can separate polyester, nylon, or cellulose from blended fabrics.

These recovered components can then be turned back into new, high-quality fibers or even raw chemical feedstocks. Companies like Renewcell in Sweden and Worn Again Technologies in the U.K. are leading efforts to scale up this process for global use.

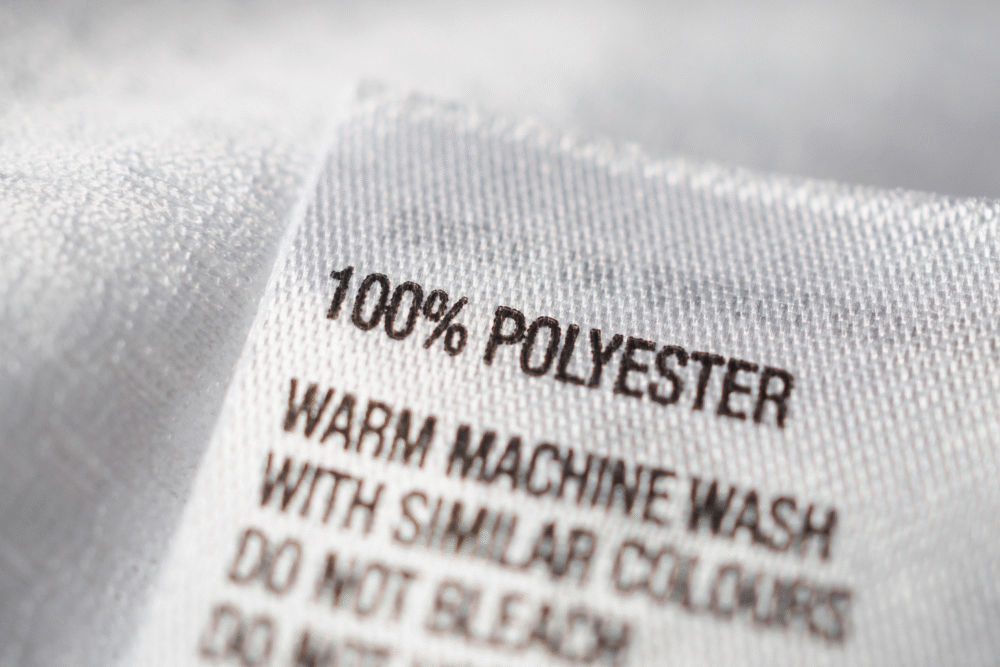

5. Polyester Recovery Is Cutting Plastic Waste

Polyester, which makes up over half of all textiles produced, is also one of the biggest recycling challenges. Fortunately, new depolymerization technologies are allowing polyester to be chemically broken down and reformed into new fibers.

Unlike traditional downcycling, this process creates material that’s virtually identical to virgin polyester. That means it can be reused repeatedly, reducing dependence on fossil fuels and keeping plastic-based textiles out of the waste stream.

6. Cotton Recycling Is Getting a High-Tech Boost

Recycling cotton has always been difficult because fibers shorten and weaken during mechanical processing. Now, new chemical methods are helping restore its cellulose structure, producing cotton-like fibers that are durable and soft.

Projects in Europe and Asia are experimenting with “dissolving pulp” techniques that convert old cotton into regenerated fibers like viscose or lyocell. This could dramatically reduce the environmental impact of cotton production, which currently requires massive amounts of water and farmland.

7. Blended Fabrics No Longer Pose a Dead End

Mixed fabrics — such as cotton-polyester blends — have historically been nearly impossible to recycle efficiently. Their fibers behave differently under heat and chemical treatment, making separation a major hurdle.

Innovators are now developing selective chemical processes that dissolve one fiber type while leaving the other intact. This approach allows blended fabrics to be recycled into pure fiber streams for the first time, opening the door to large-scale textile recovery.

8. Automation and AI Are Transforming Textile Sorting

Sorting post-consumer textiles has always been labor-intensive and error-prone, but automation is changing that. AI-powered scanning systems can now identify fiber types and fabric blends in seconds using near-infrared sensors.

These smart systems make recycling plants faster, cheaper, and more accurate. By improving sorting precision, they help ensure that each textile is sent to the right type of recycling process, boosting recovery rates across the industry.

9. Industrial Uses Are Expanding Beyond Fashion

Recycled textile fibers are increasingly being used in sectors far beyond clothing. Construction companies are testing them as insulation materials, car manufacturers are incorporating them into interiors, and chemical firms are repurposing them for new compounds.

This diversification means textile waste can support multiple industries simultaneously, helping replace virgin raw materials and reducing overall environmental impact. It’s a shift that’s turning textile recycling into an important part of the broader circular economy.

10. Governments and Brands Are Driving the Shift

Countries across Europe and Asia are implementing policies that make textile producers responsible for the waste they create, a strategy known as Extended Producer Responsibility (EPR).

Major fashion and manufacturing brands are also setting recycling targets and investing in circular supply chains. This regulatory and corporate pressure is accelerating the adoption of recycling technologies and encouraging consumers to view textiles as resources rather than waste.

11. Toward a Future of Circular Textiles

The ultimate goal for researchers and policymakers is a fully circular textile economy — one in which materials are continually reused instead of discarded. Achieving that will require large-scale recycling infrastructure, consumer participation, and supportive legislation.

With breakthroughs in chemistry, automation, and material design, that vision is becoming increasingly realistic. The global textile industry, once defined by waste, may soon become a model for sustainable resource recovery and innovation.