Researchers uncover quarry marks that may explain how Egyptians carved granite using copper and sand.

For centuries, archaeologists have marveled at how the ancient Egyptians carved temples, statues, and obelisks out of solid granite—some weighing hundreds of tons—long before the invention of steel or modern power tools. Recent discoveries in ancient quarries, including the unfinished obelisk at Aswan, are revealing more about how they did it. Evidence suggests the Egyptians used copper chisels, dolerite pounding stones, and quartz sand as an abrasive to cut and polish even the hardest rock. The process was slow, labor-intensive, and astonishingly precise, showcasing the ingenuity of one of history’s greatest engineering civilizations.

1. Granite Was the Egyptians’ Hardest Challenge

Granite, found mainly in southern Egypt near Aswan, is one of the hardest natural stones on Earth, ranking around 6–7 on the Mohs scale. It’s significantly tougher than the limestone and sandstone used in most pyramids and temples.

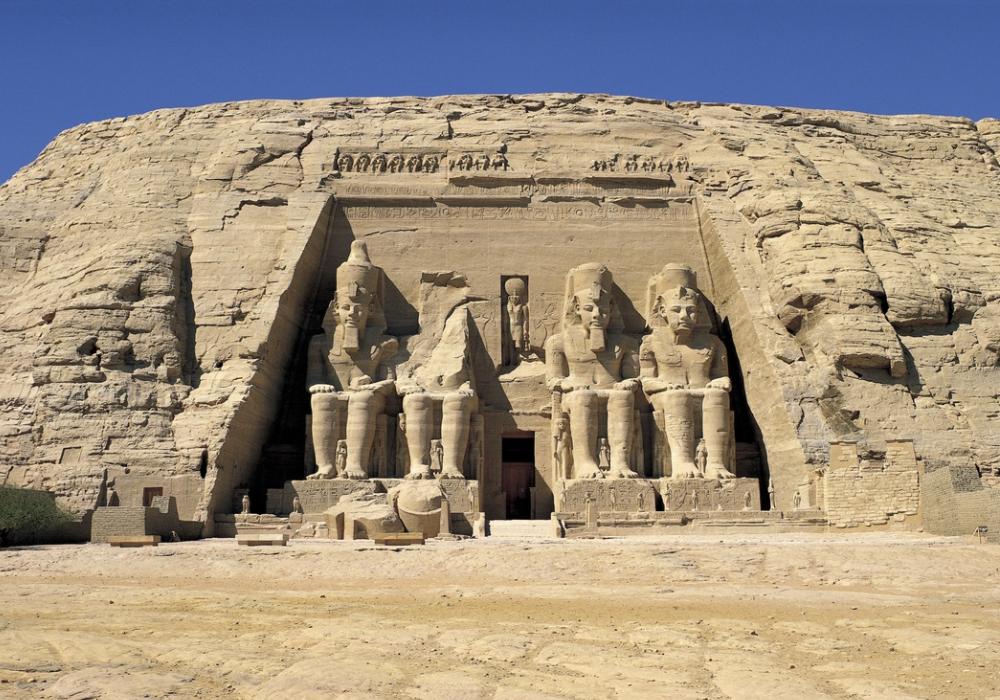

Yet granite was chosen for the most important monuments—such as the inner chambers of pyramids, colossal statues, and sarcophagi—because of its durability and association with eternity. Its hardness, however, posed immense challenges for ancient builders who had only copper and stone tools at their disposal.

2. Copper Tools Were Key—Despite Being Softer Than Granite

The Egyptians primarily used chisels, saws, and drills made of copper, a metal softer than the stone they were cutting. On its own, copper could not slice through granite. But when combined with quartz sand as an abrasive, the tools became far more effective.

Archaeological finds, including copper saw fragments and tubular drill cores, show that workers packed the gaps between tools and stone with sand. The abrasive grains did the cutting, while the copper simply held the grit in place and directed the motion.

3. Sand Was the True Cutting Agent

Quartz sand, abundant in Egypt’s deserts, was harder than both copper and granite. By embedding this sand in water or slurry and using back-and-forth motion, ancient craftsmen could grind slowly through solid rock.

This abrasive technique produced smooth, flat surfaces and clean cuts, though at a painstakingly slow pace. Experiments by modern archaeologists have confirmed that this method can reproduce ancient tool marks, proving it’s both plausible and effective.

4. Dolerite Hammerstones Shaped the Rough Blocks

Before finer cutting began, Egyptian quarry workers used dolerite pounding stones to break rough blocks from bedrock. Dolerite, a dark igneous rock even harder than granite, could withstand repeated impact without shattering.

Workers would strike the surface thousands of times to loosen and shape the stone. Many of these dolerite hammerstones—some weighing 10 to 20 pounds—have been found littered around ancient quarries like Aswan, offering direct evidence of this early stage of extraction.

5. The Unfinished Obelisk Offers the Best Evidence

At the granite quarries of Aswan lies a massive obelisk left unfinished due to cracks forming during construction. Measuring about 137 feet long, it would have weighed roughly 1,200 tons if completed.

The obelisk’s partially carved trenches reveal distinct tool marks made by dolerite pounders and abrasives. These preserved surfaces give archaeologists a rare, in-situ record of how ancient workers shaped enormous monoliths directly from the bedrock using primitive yet effective techniques.

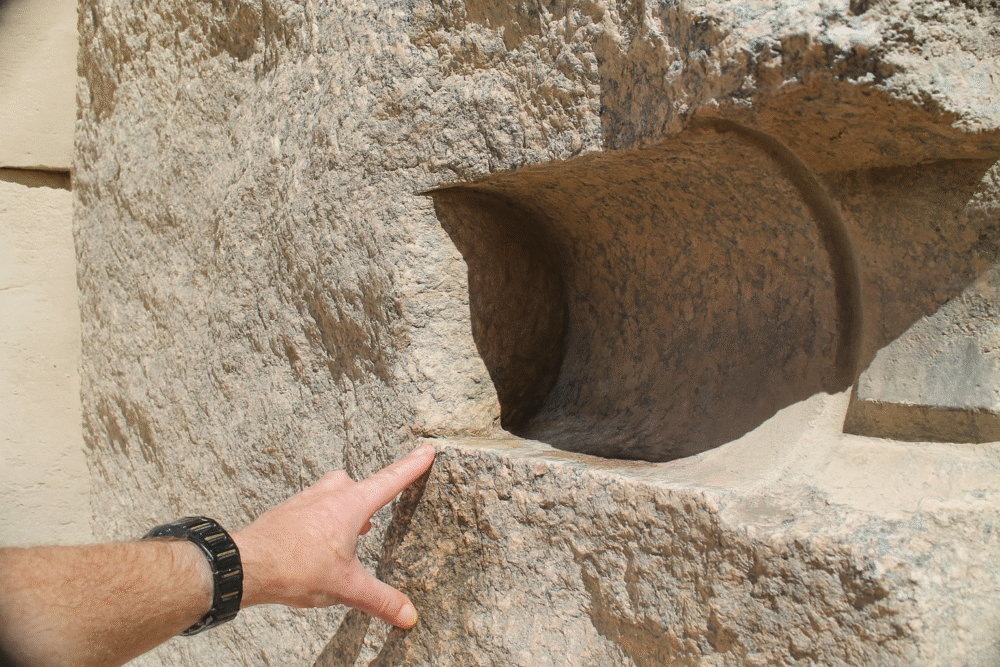

6. Tubular Drilling Was Used for Precision Work

Egyptian artifacts show clear evidence of circular drill holes—some remarkably uniform. These were likely created with copper tube drills packed with quartz sand and rotated manually, possibly with a bow or weighted handle.

Experimental archaeology has replicated these distinctive spiral grooves using this same method. The technique allowed for precision drilling of stone vessels, statues, and architectural elements. The smoothness and consistency of these ancient drill holes highlight the Egyptians’ mastery of controlled abrasion.

7. Bronze and Later Iron Tools Improved Efficiency

By the New Kingdom period, around 1500 BCE, Egyptians began incorporating bronze tools, which contained tin and were harder than pure copper. These advances improved durability and cutting power, especially for carving detail into granite surfaces.

There’s limited evidence of early iron use before widespread adoption in later centuries, but these gradual material improvements reduced labor time and made previously impossible tasks more achievable—laying the groundwork for increasingly ambitious stone projects.

8. Stone Saws Were Used to Shape Massive Blocks

Archaeologists have uncovered traces of saw marks on granite slabs and statues, indicating that ancient builders used copper saws fitted with sand slurry to make precise cuts. These saws could be up to 2.5 meters long and required several workers to operate in unison.

The process likely took days or even weeks for a single cut, depending on depth and hardness. Experiments using reconstructed tools confirm that such sawing could indeed slice through granite when aided by abrasive sand, proving the technique’s practicality and accuracy.

9. Polishing Was a Multi-Stage Process

After the rough carving, artisans polished granite surfaces using progressively finer abrasives. Quartz sand was followed by powdered emery or crushed stone to achieve the mirror-like finishes seen on statues and sarcophagi.

The final polishing could take as long as the carving itself. The smooth, reflective finish on monuments such as the Red Pyramid and the statues of Ramses II demonstrate the Egyptians’ commitment to craftsmanship and their deep understanding of materials and technique.

10. Modern Experiments Confirm the Ancient Methods

Archaeologists and engineers have tested these ancient techniques using authentic tools and materials. Replication experiments by researchers like Denys Stocks have shown that copper tools combined with quartz sand can reproduce the exact marks found on ancient Egyptian monuments.

These findings reinforce that no lost technology or advanced machinery was needed—only ingenuity, patience, and teamwork. The results reveal the Egyptians’ mastery of physics and materials, proving that skill and persistence, not mystery, allowed them to carve the hardest stones in the ancient world.